3D Scanning & Reverse Engineering:

Measure, Inspect & Digitize Your Parts

MMB VOLUM-e offers advanced 3D scanning solutions for both prototype and series production parts. Using high-performance 3D scanning and dimensional measurement tools, we generate high-precision 3D files for reverse engineering, allowing the redesign or optimization of existing parts, or for geometric measurement & quality control, ensuring production validation with the highest accuracy

Reverse Engineering: Recreate Your Parts Without a 3D File

Reverse engineering allows for the generation of usable 3D files from a 3D scan of an object. Using a point cloud captured by a 3D scanner, the data is transformed into precise, functional CAD files.

Advantages of Reverse Engineering with 3D Scanning:

- Precision: Accurate and detailed measurements for ultra-precise digital models.

- Speed: Capture millions of points in seconds, ideal for complex objects.

- Flexibility: Scan objects of any size, shape, or material.

- Non-destructive: Preserves valuable or fragile parts without alteration.

Applications:

- Reproduction of discontinued spare parts

- Creation of plans from existing or lost parts

- Scanning for industrialization or duplication

- Geometry analysis of manually modified tools

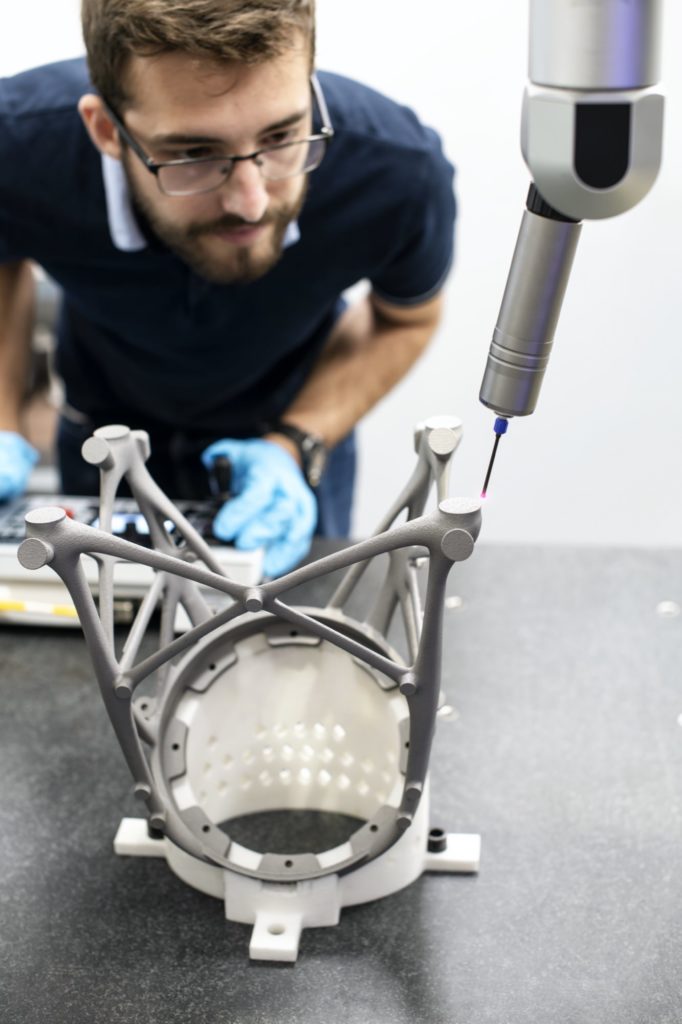

MMB VOLUM-e Dimensional Measurement Processes:

- 3D Measuring Machine (CMM): The Zeiss Contura measures points on the physical part with high reliability (length error margin: E0 = 1.5 + L/350 µm) across a measurement range of 1000 x 1200 x 600 mm, comparing them to the corresponding CATPART file of the theoretical part.

- 3D Scan: The Atos Gom Triple Scan scans the entire part and generates a 3D model in STL format. By comparing it to the theoretical part file, it quickly estimates dimensional defects at specific points and visually identifies any surface deformations or micro-cracks. Fast and precise, it has a wide measurement volume and can scan parts with dimensions ranging from 170x170x170mm to 700x700x700mm.

3D Scanning: Capture, Measure & Control Your Parts with Precision

Using our optical 3D scanner, MMB VOLUM-e captures the geometry of your parts and converts them into precise 3D files. Our expertise covers non-contact measurement and 3D inspection, even for complex geometries.

A Precise Scanning Process:

- Multiple captures: Analyzing the object from different angles for a comprehensive result.

- Dense point cloud: Faithful reproduction of the object, from overall dimensions to the finest details.

- Advanced software: Accurate calculation of the 3D positions of characteristic points.

Comprehensive & Reliable Inspection:

- Detailed inspection report to ensure compliance.

- Complete analysis: Geometric, dimensional, and deformation analysis under load.

- Purposes: validation of theoretical gaps, thicknesses, free or assembled parts, etc.

Applications:

- Preventive inspection: Validate prototypes or pre-series parts.

- Verification inspection: Analyze samples during production.

- Corrective inspection: Resolve issues during manufacturing.