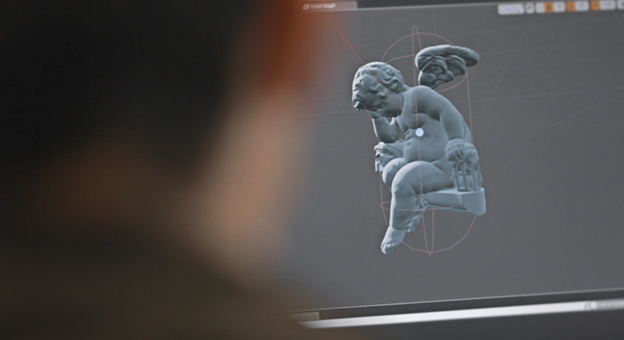

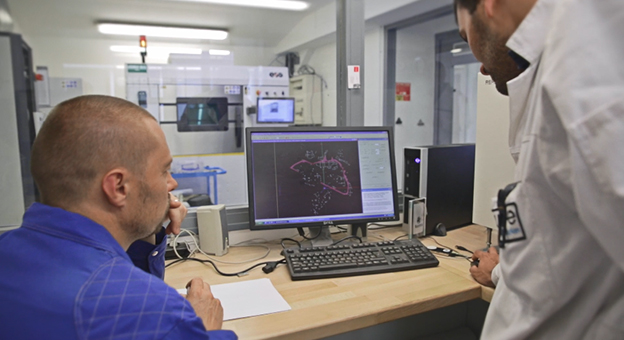

Industrial engineering consists primarily in digital 3D modeling or computer-aided design (CAD) and production planning and preparation or computer-aided manufacturing (CAM). Both steps are often grouped under the CAD/CAM acronym dur to their continuity. A third step consists in simulations of the part’s dynamic features in its intended environment, i.e., the system, with advanced engineering tools.

The MMB engineering team either designs tooling or parts from the ground up (a set of specifications) or more often modifies the customer, or product designer, provided drawing (2D or 3D) to improve the feasibility and reduce production costs. In essence, the MMB engineering team defines each project’s manufacturing strategy as an optimal sequence of operations. The MMB Engineering Desk is organized by production process family, i.e. : polymer additive manufacturing (AM), metal AM, and CNC machining. There are specific levers to each techology, but the objectives remain the same : meet specifications, simplify operations, save raw material and time.